-

LATEST NEWS / PRODUCT & TECHNOLOGY2 Min Read

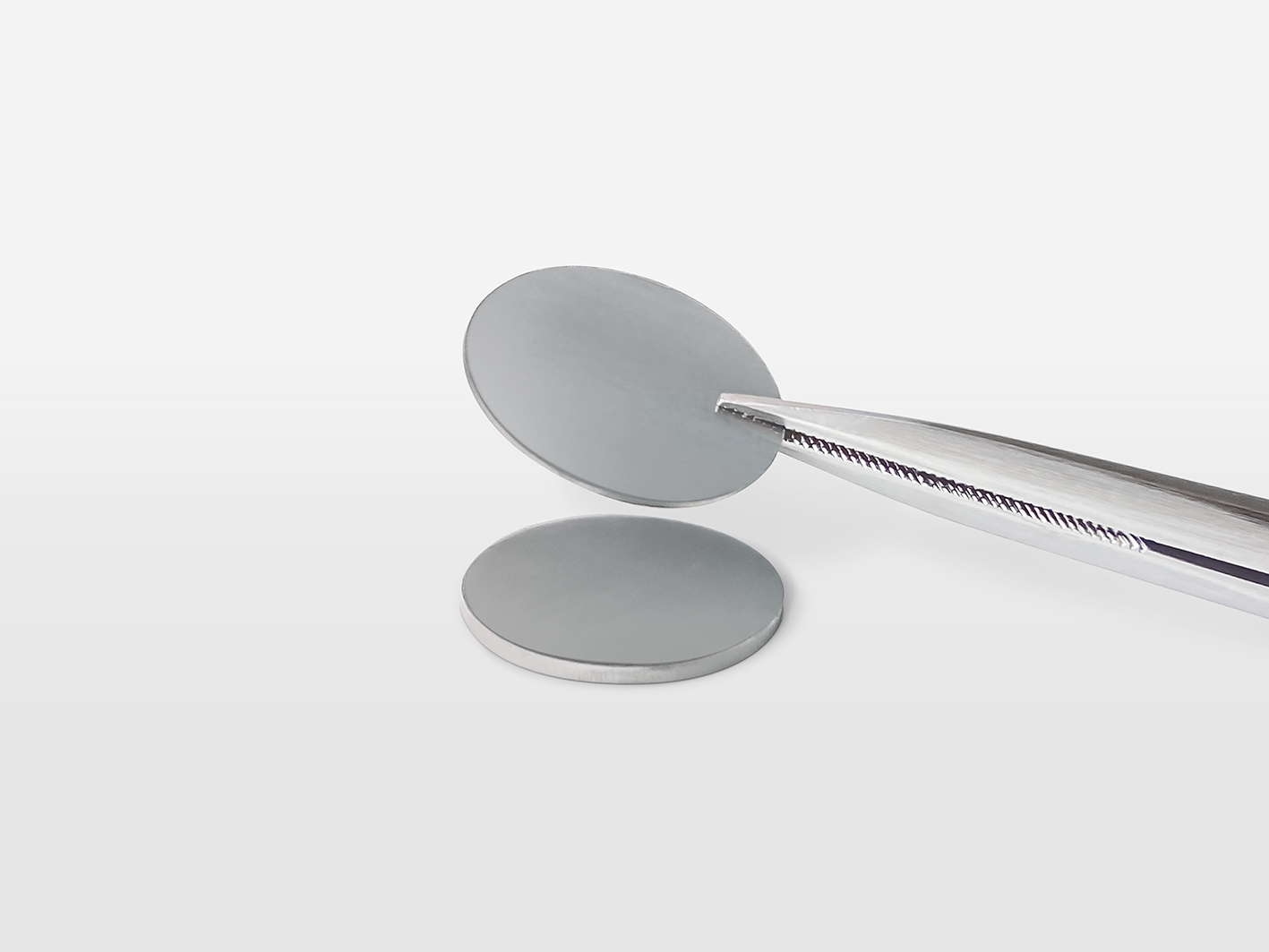

DISCO Corporation has developed a process for diamond wafer manufacturing that applies the KABRA process, an ingot slicing method using laser technology. This process contributes to increasing the diameter of diamond wafers.

Diamond is often called the “ultimate semiconductor material” due to its superior material characteristics compared to Si, SiC, and GaN. In particular, as diamond has excellent insulation strength and heat conductivity, it is expected to be a good material for power semiconductors, and device development is underway at various research institutes.

On the other hand, as it is an extraordinarily hard material, it came to be known that it is difficult to process mechanically. Therefore, laser became the general method used to slice wafers from a diamond crystalline ingot. However, with the conventional laser slicing method, as the ingot is processed from the sidewall, there was a limitation on the ingot diameter, and it was difficult to increase it.

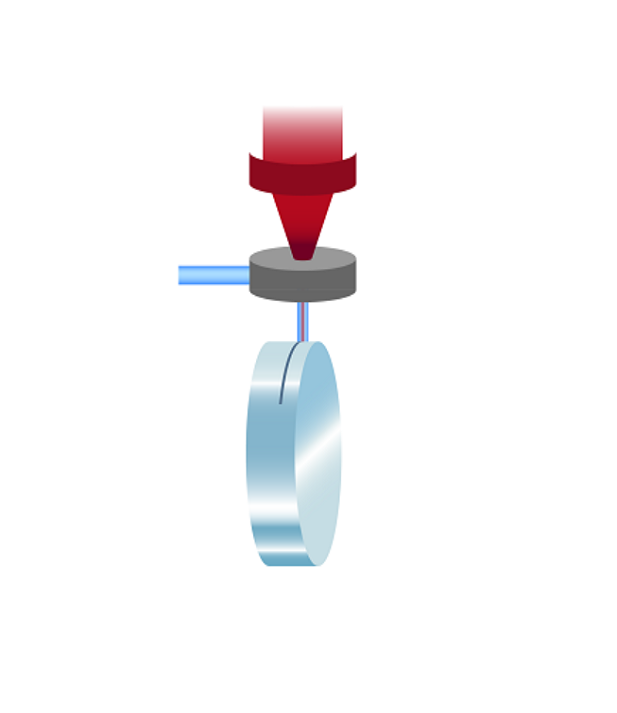

With KABRA slicing, there is no limitation on the ingot diameter as the laser is irradiated from the upper surface of the ingot, making it possible to increase the ingot diameter.

Figure 1: Conventional slicing method using laser

Figure 2: KABRA for diamond processing

Features:

- Supports large-diameter ingots exceeding Φ50 mm

With the conventional method where the laser is irradiated from the sidewall of an ingot (Figure 1), the largest supported diameter was approx. Φ30 mm, but with the KABRA method (Figure 2), as the laser is irradiated from the upper surface of the ingot, there is no limitation on the ingot diameter. - Splitting wafers with a thickness of 100 µm or less is possible

By irradiating the laser at a shallow depth from the upper surface of the ingot, it is possible to split thin wafers. Therefore, a larger number of split wafers can be expected compared to the conventional method. - Achieves equivalent or higher throughput compared to the conventional method

The splitting speed is equal to or faster than the conventional method, achieving lower processing costs.

In addition, 45 patents related to this technology have been registered. Test cuts are available. Contact a DISCO sales representative.

Original – DISCO

- Supports large-diameter ingots exceeding Φ50 mm

-

LATEST NEWS3 Min Read

DISCO Corporation has newly developed the following dicing blades: ZHSR Series, TM22 Series, and BH23 Series, and the following dry polishing wheel: DPEG Series SZ Type for the semiconductor and electronic components market. These products are being exhibited at SEMICON Japan 2023 (December 13–15, Tokyo Big Site).

ZHSR Series: Hub Blade for Silicon Wafer Dicing

With the recent progress in miniaturization within the semiconductor manufacturing process (e.g., logic memory), thorough countermeasures against static electricity are required. Highly pure water is used as a coolant and for cleaning during the wafer dicing process, but since highly pure water is nonconductive, a common countermeasure is to dissolve CO2 to provide conductivity. However, if the concentration of CO2 in the highly pure water is increased to suppress the amount of static electricity, corrosion will occur in electroformed blades.The ZHSR Series has achieved improved corrosion resistance while maintaining high processing quality.

Features:

- Newly developed bond material

- Significantly improved corrosion resistance

- Improves yield by reducing wavy cutting and breakage due to blade tapering

- Promotes self sharpening and achieves high-quality processing

TM22 Series: High-Rigidity Metal Bond Blade

For passive components, such as condensers, die shape and volume after dicing affect product performance. Therefore, high dimensional accuracy is required from processing. As a successor to the TM11 Series, the TM22 Series can achieve high-precision processing with its increased bond strength and can contribute to improved productivity.

Features:

- Newly developed bond with increased strength

- Improves die dimensional accuracy after processing

- Improves yield by reducing wavy cutting and breakage due to blade tapering

BH23 Series: Metal/Resin Bond Blade Compatible with ABC (Automatic Blade Changer)

ABC is a function that automatically replaces hub blades during silicon wafer dicing. This function is recognized for its contributions in preventing operator error and improving operation rate. This automation is currently also in demand for metal/resin bond blades used to dice electronic components and packaging. With an aluminum hub bonded to its metal/resin blades, the BH23 Series is compatible with ABC, thus promoting automation.

Features:

- Supports metal, resin, and other bonds

- Individual blade information engraved to hub as 2D code

- Automatically sends actual measurement values for blade exposure and thickness to equipment

- Prevents human error such as blade mounting errors and/or value input errors

- Automatically records serial number of blades used, ensuring traceability

- Reduces downtime caused by wait for operator to start operation

- Improves equipment operation rate

DPEG Series SZ Type: Gettering DP Wheel for Silicon Wafers

In order to increase the strength of the wafer in silicon wafer thinning, undulations on the grinding surface need to be removed. However, if undulations are completely removed, the gettering effect is lost, leading to wafer property errors due to heavy metal contamination. The DPEG Series SZ Type has been newly added to the gettering DP wheel lineup for solving this issue. The DPEG Series SZ Type can achieve higher die strength than the conventional product while maintaining the gettering effect.

Features:

- Improved pad composition

- Improves die strength by approx. 1.3 times while maintaining gettering effect (when compared with conventional product)

Original – DISCO

- Newly developed bond material

-

DISCO Corporation has developed DAG811, which has improved usability and a space-saving footprint, as the successor to DAG810, an automatic grinder that has responded to a wide range of needs and has been well received for many years. This equipment is being exhibited at SEMICON Japan 2023 (December 13-15, Tokyo Big Site).

Since its release in 2002, DAG810 has been used for R&D and semi-mass production in a wide range of fields such as semiconductors, electronic components, and optical components. In response to the increasing demand related to applications, DAG811 was developed upon renewing the equipment specifications such as improving the operability and making it compact.

By optimizing the processing point, this equipment also meets the grinding needs of compound semiconductors such as SiC and GaN used in power devices, for which demands are increasing.

Features

Improved Usability

- Easier wheel replacement with an optimized internal layout

- Enlarged monitor size from 10.4 inches (existing model) to 15 inches

・A new GUI (Graphical User Interface) has been adopted for improved operability

Space-saving Design

- Footprint reduced by over 12% compared to the existing model

・With a footprint of approx. 0.9m², it is one of the world’s smallest 1 spindle, 1 chuck table grinders (compatible with Φ8-inch wafers)

Supports a Wide Range of Grinding Demands

- Supports two types of grinding methods, in-feed grinding and creep-feed grinding

Easy switching between the methods using the touch panel - Achieves good grinding results for compound semiconductors as well due to optimization of the processing point

Original – DISCO

-

DISCO Corporation has developed DDS2020, a fully automatic die separator that supports Φ200 mm tape frames and achieves separation of hard materials including SiC and sapphire. This equipment is being exhibited at SEMICON Japan 2023 (December 13-15, Tokyo Big Site).

Stealth dicingTM is a dicing process where a modified layer is formed by focusing a laser beam inside the workpiece, following which stress is applied externally to separate it into die. As silicon wafers can be separated with a relatively small amount of stress, the die can be separated by simply expanding the dicing tape. On the other hand, materials that have high mechanical strength like SiC wafers that are widely used for power devices and sapphire wafers used for LED cannot be separated just by expansion. Thus, a breaking mechanism was necessary.

DDS2020 is a die separator that achieves separation of hard materials such as SiC and sapphire with a low load using a new breaking mechanism.

Features

- New breaking mechanism that achieves low load separation

- Load decreased by 40% compared to the conventional breaking mechanism

- Breaking load measurement and graph display

- Detects unseparated die and improves the yieldAutomatic retry setting when unseparated die are detected is also available

- Tape frame remounting for breaking is no longer necessary

- Eliminates remounting work and reduces tape costs

Original – DISCO

- New breaking mechanism that achieves low load separation

-

DISCO Corporation has developed a new ABC (Auto Blade Changer) that can automatically replace hubless blades as an optional function, and it is currently available for purchase. This function is planned to be exhibited at SEMICON Japan 2023 (December 13 – 15, Tokyo Big Sight).

Developmental Background

Dicing saws were originally developed to singulate fully-manufactured semiconductor wafers, but in recent years, dicing saws are also being used in applications such as package dicing following resin molding (QFN packages, etc.), passive component dicing such as condensers and inductors, and dicing optical parts that use glass.

When dicing silicon wafers, the blade used is called a hub blade, and it is attached to an aluminum hub. The Auto Blade Changer (ABC), an automatic replacement function for these hub blades, was developed and has been sold by DISCO since 2005, and has contributed to the improved productivity of the dicing process and the reduction of human errors.

However, manual replacement by an operator was necessary to replace hubless blades that are widely used in applications such as package dicing as mentioned above. This newly developed ABC supports both hubless and hub blades, enabling automatic replacement regardless of the blade type.Features

The new ABC supports blade replacement of both hubless and hub blades.

- Improves operation rates

- Reduces downtime caused by waiting for the operator

- Prevents human error

- Reads the blade ID using a QR code, and automatically fills in values such as the blade exposure

- Contributes to traceability

- Records the blade lot ID used

Supported models

The new ABC can currently be installed in the following three equipment models.

DFD6342:A facing dual spindle dicing saw that supports Φ200 mm wafers

DFD6561:A facing dual spindle dicing saw that supports Φ300 mm wafers

DFD6755:A facing dual spindle dicing saw with two chuck tables specialized for package dicingOriginal – DISCO

- Improves operation rates

-

DISCO Corporation has made a decision to build a new building at the Haneda R&D Center (Higashi Kojiya, Ota-ku). Construction will begin in April 2025 and is scheduled for completion at the end of March 2027. With the construction of the new building, DISCO aims to further enhance its R&D functions, enabling it to respond to the future needs of the semiconductor and electronic component markets.

The existing buildings, which were acquired in March 2022, were originally designed and built by a previous owner for training flight crews and as a data center. As these buildings have a relatively large amount of floor space with high load-bearing capacity, they were put into use as a development site upon the fitting of utilities such as water supply, drainage, and compressed air.

However, with the recent increase in development, DISCO has decided to construct a new building with an increased amount of floor space suitable for development. This new building will be constructed such that it can be expanded if more floor space for development becomes necessary.

Two of the seven existing buildings will be demolished to make room for the new building. The five remaining buildings will continue to be used with the purpose of R&D, as well as enhancing DISCO’s production system during periods of high demand.

Original – DISCO

-

DISCO Corporation opened a new mid-process research center on July 1, 2023.

As the wafers on which circuits are built in the front-end process of semiconductor manufacturing have extremely high added-value, high yield is required in the processes that follow. Among these processes, in the grinding (wafer thinning) and dicing (wafer singulation through cutting) processes handled by DISCO, there is a risk that one processing failure may cause the entire wafer’s quality to deteriorate.

Therefore, caution and accuracy are required for operations such as processing and transfer in particular. In addition, if a large number of defects occur in the back-end process, most of the time, alternative wafers cannot immediately be supplied from the front-end process. As a result, this may have a significant impact on the entire supply chain and become a large issue in the lean manufacturing of the automotive industry.

Recognizing these issues, DISCO has newly positioned these processes that are conventionally in the back-end process of semiconductor manufacturing as part of the “mid-process,” and has been proceeding with R&D in this area.

DISCO has officially established the mid-process research center as a site to conduct R&D for the mid-process and perform demonstrations for customers. This center has permanent installations of the wafer transfer system RoofWay as well as the cluster system MUSUBI, and research is underway to reduce the equipment operator’s responsibilities and improve semiconductor wafer processing and transfer quality through automation of the production system.

As semiconductor use in automotive applications is increasing, stricter quality management is being required for semiconductors as well, as they are responsible for the user’s life. Therefore, through this center, DISCO will aim at realizing a production system that eliminates operator intervention as much as possible in order to reduce quality variation that arises from human involvement.

The mid-process research center is a facility that makes verification of unmmaned processes possible by connecting a series of processes with a fully automatic transfer robot. The processes include thinning using a grinder, singulation using dicing saws and laser saws, and pickup, inspection, and measurement of die.

The mid-process research center has been partially open since December 2021, and during the time until the official opening, DISCO has been improving the level of the system by incorporating the valuable opinions of some of the invited customers. Now, as some time has passed from when the category of COVID-19 was downgraded and reclassified as a level 5 infectious disease, DISCO felt that it was finally possible to proactively welcome visitors to the center, and thus decided to make an official announcement for the opening of the center.

Original – DISCO